Standardize Palletizing with One Interface Across Projects

Standardize Palletizing with One Interface Across Projects

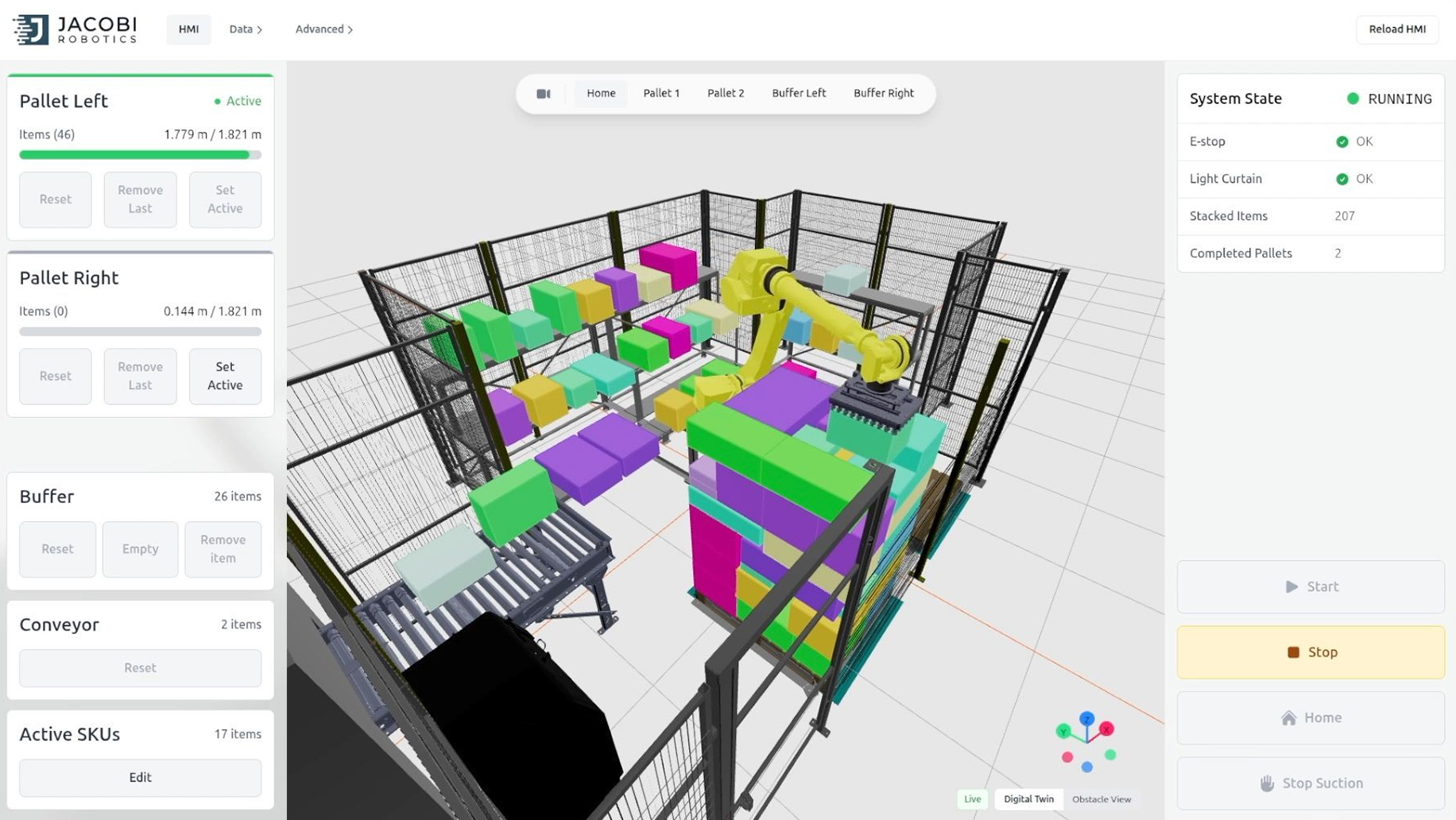

One palletizing interface for every deployment.

Deploy mixed-case and single-SKU palletizing systems using a consistent interface — reducing project-to-project variation, simplifying commissioning, and lowering long-term support and training costs across customer sites.

What's Broken Today

Every palletizing project reinvents the interface

Across projects, palletizing HMIs are often rebuilt from scratch or heavily customized. Button layouts, fault messages, recovery flows, and configuration screens vary by customer, site, and engineer — increasing complexity with every deployment.

Inconsistent interfaces increase commissioning and support effort

When interfaces differ from one project to the next, commissioning teams spend valuable onsite time re-learning controls and validating edge cases. After go-live, support teams struggle to diagnose issues quickly because behavior and terminology are not standardized.

Knowledge stays locked to a few engineers

Operational nuance — how to recover from faults, how to handle exceptions, how to adjust pallet behavior — often lives in the heads of experienced engineers. As teams scale, this creates bottlenecks, training challenges, and risk when key individuals are unavailable.

With the OmniPalletizer

Modern palletizing systems no longer need to be defined by custom logic and bespoke interfaces.

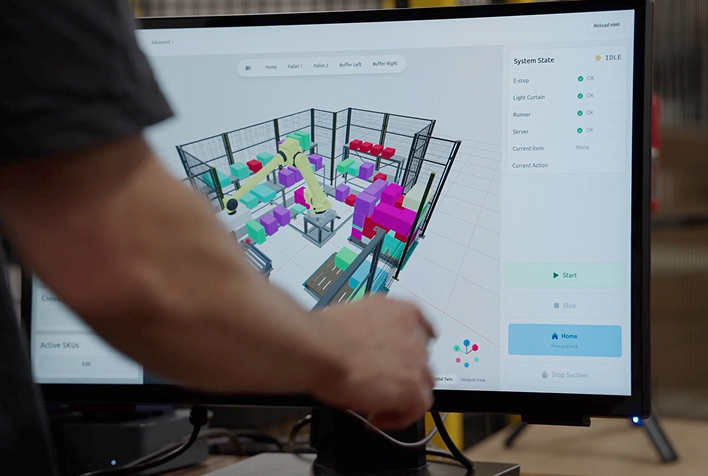

Instead of rebuilding controls and workflows for every project, integrators can now deploy a consistent palletizing interface that reflects how intelligent palletizing systems actually operate — adapting to variability while guiding operators clearly when human input is required.

This allows integrators to standardize the palletizing experience without sacrificing flexibility for different customers, layouts, or industries.

How the OmniPalletizer Solves It

Jacobi's OmniPalletizer provides a unified palletizing interface designed to scale across projects.

It enables integrators to:

Deploy a consistent operator and engineer workflow across mixed-case and single-SKU palletizing cells

Standardize fault handling, recovery steps, and operator prompts for predictable behavior onsite

Configure palletizing behavior through software settings instead of custom HMI logic

Reduce commissioning time by reusing familiar controls and workflows

Train operators and support teams once — and reuse that knowledge across deployments

The same interface philosophy applies whether the cell handles inbound palletizing, grocery, LTL, or store-ready pallets.

Business Impact

Faster commissioning through reuse of familiar interfaces and workflows

Lower long-term support and maintenance burden

Reduced dependence on individual engineers’ tribal knowledge

More predictable operator experience across customer sites

Scalable palletizing deployments without scaling interface complexity

The New Standard for Palletizing

OmniPalletizer becomes a standard palletizing interface — one that can be deployed repeatedly across customers and projects.

Instead of delivering a different palletizing experience every time, integrators can focus on system design and value engineering, knowing that operators, support teams, and engineers will interact with a familiar, proven interface on every deployment.