Parcel Mixed-Case Palletizing

Automate Parcel Mixed-Case Palletizing Operations

Mixed-case palletizing that adapts in real time.

Build freight-ready, optimized pallets for various shipping carriers as orders arrive, automatically adjusting stack composition and stability without predefined recipes, fixed sequencing, or operational disruption.

What's Broken Today

Carrier mix-ups drive rework

Manual mixed-case palletizing in grocery DCs is repetitive, physically demanding work — often performed in chilled environments. Even when staffing exists, it’s difficult to retain associates in roles that combine constant lifting with cold conditions and high pace.

Unstable parcel stacks create safety risk

Small, lightweight cartons mean many parcels per pallet and poor stackability. Loads shift and topple, triggering constant re-stacking—more lifting, twisting, and re-handling, especially during peak.

Right-sized packaging breaks patterns

With Packsize-style right-sizing, box dimensions are effectively infinite. Each pallet becomes a new 3D puzzle, so fixed patterns and traditional automation fail without frequent intervention.

With the OmniPalletizer

Recent advances in real-time perception, decision-making, and robot motion have made a new approach possible.

Instead of forcing variability out of the system, automation can now respond to it — dynamically and continuously — as conditions change on the floor.

This shift enables palletizing systems that adapt to new orders as they arrive, without predefined recipes or perfect sequencing.

How the OmniPalletizer Solves It

OmniPalletizer is designed for environments where every pallet is different.

It continuously:

Observes incoming cases in real time, without relying on pre-defined order structures

Reasons about stack stability, density and height

Executes safe, efficient robot motions optimized for speed and reliability

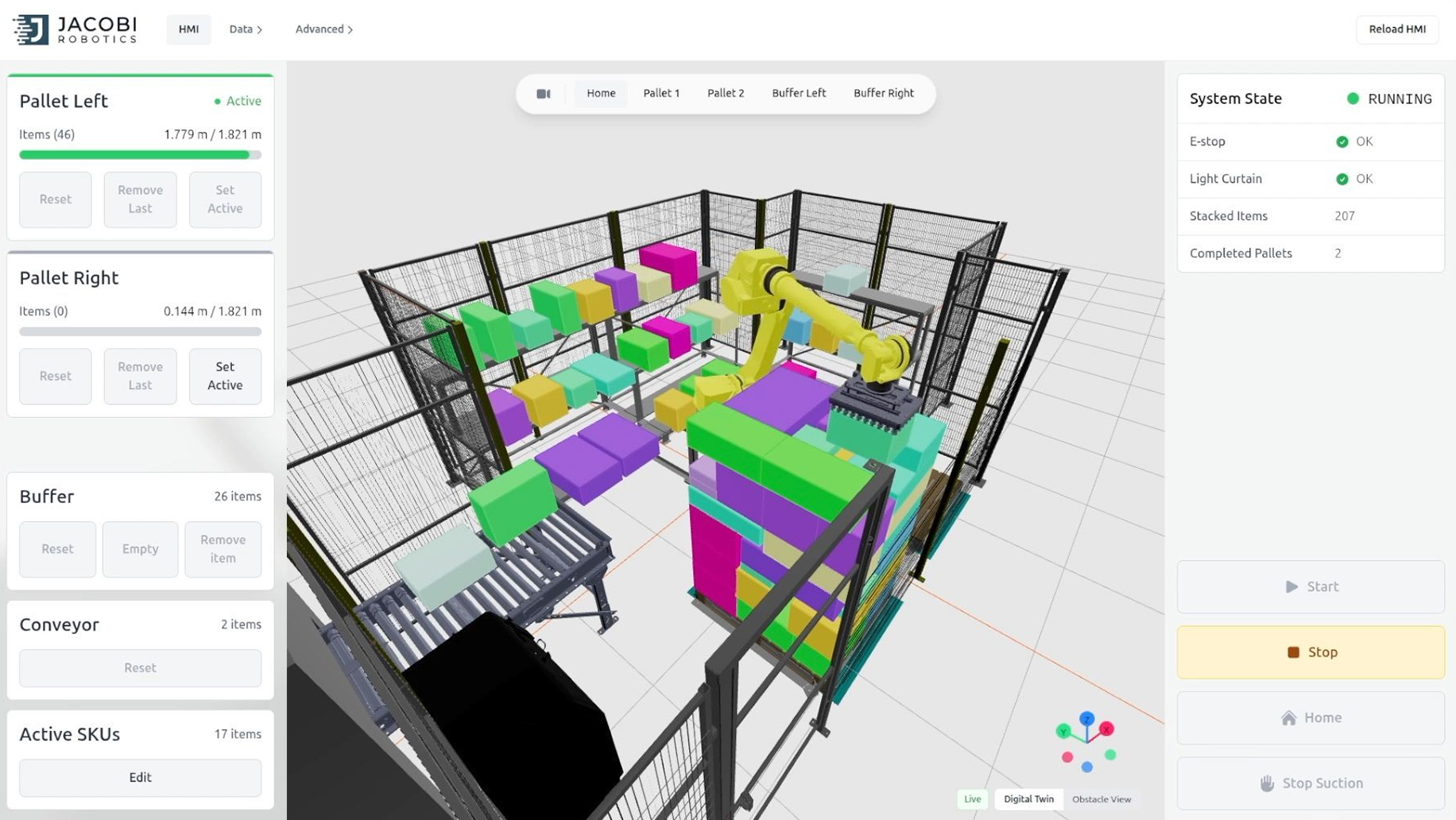

Alerts operators when it needs help with clear step-by-step instructions and a user friendly interface

Business Impact

Reduced dependence on manual palletizing labor

Improved safety in high-variability environments

Higher throughput and reduced errors during peak and irregular demand

Automation that scales with operational complexity