Latest Articles

Why Traditional Automation Needed Perfect Sequencing And Why OmniPalletizer Doesn't

Perfect sequencing has been the traditional workaround for mixed-case palletizing's complexity, but it comes with significant costs and limitations.

DHL Awards Innovation Partnership to Fast Forward Challenge Winner

Jacobi Robotics to deploy OmniPalletizer with DHL following Fast Forward Challenge victory — a collaboration that advances mixed-case palletizing and supply chain automation.

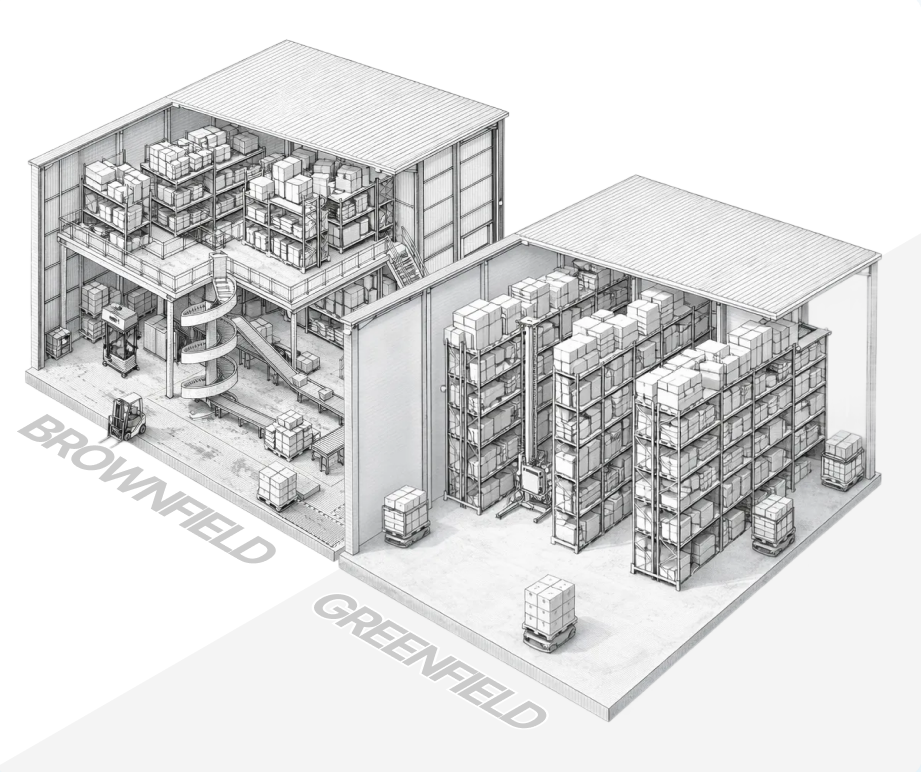

Brownfield Reality: Why Most Warehouses Aren’t Designed for Automation

Greenfield sites are easy; brownfield is where automation goes to die. We break down why most warehouses—with their legacy layouts and chaotic workflows—reject "perfect" robotic solutions and what actually works in the wild.

Mixed Case Deployment with Delta Tech

Delta Technology deployed Jacobi's OmniPalletizer to automate mixed-case palletizing in a live parcel operation, removing workers from repetitive injury-prone tasks while handling dozens of SKUs with no upstream sequencing required.

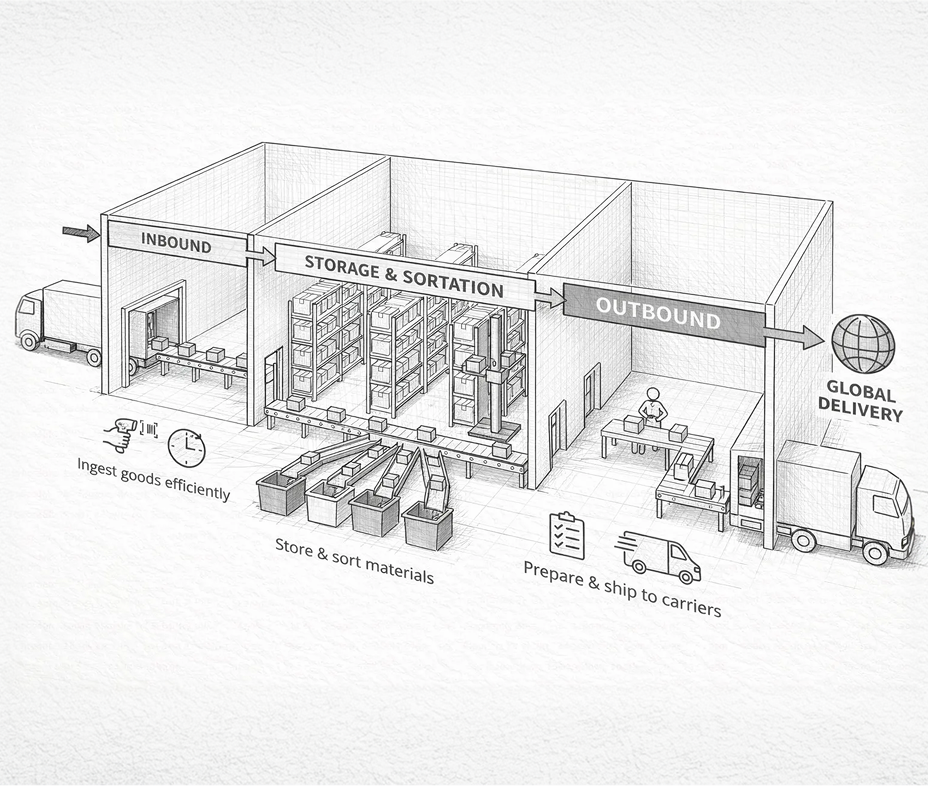

The Automation Gap No One Talks About: Mixed-Case Palletizing

Mixed-case palletizing is a structural automation gap—one of the most common, physically demanding, and operationally consequential workflows that still relies on people.

What Makes Store-Ready Pallets Hard? A Look at the Rules Operations Care About Most

Anyone who has worked in outbound fulfillment knows that store-ready palletizing is governed by a surprisingly intricate hierarchy of business rules.

Partner Spotlight: Marcel van Schijndel on the Future of Warehouse Automation

We sat down with Marcel van Schijndel, CEO and owner of WSR Solutions, to discuss the future of robotics and warehouse automation.

Photoneo and Jacobi Robotics Partner to Deliver AI-Powered Robotic Automation for Warehouses

The first showcase of advanced mixed palletizing solution at ProMat 2025 illustrates the combined power of 3D vision and AI-driven robotics, delivering unprecedented efficiency, scalability, and cost savings for warehouses and distribution centers.

Welcoming Mathias Wiklund to Jacobi Robotics’ Advisory Board

Jacobi Robotics welcomes Mathias Wiklund, a global leader in robotics and automation, to its Advisory Board to help drive scalable, accessible robotics solutions.

Torfresma Integrates Jacobi Robotics' AI to Enhance Palletizing Solutions

Jacobi Robotics’ AI software cuts palletizer deployment time by 95%, reducing setup from weeks to hours.

AI Startup Jacobi Robotics Launches with $5 Million Seed Round and Motion Planning Breakthroughs to Program Robots 20x Faster

A 95% reduction compared to traditional robot programming methods, Jacobi has set a new industry standard for robot deployment time.