Inbound Palletizing from Floor-Loaded Trucks and Containers

Automate Inbound Palletizing from Floor-Loaded Trucks and Containers

Inbound palletizing that adapts to unknown cases.

Automatically build stable, dense single-SKU pallets for storage as cases are unloaded — measuring box dimensions in real time and generating pallet patterns on the fly, without relying on advance item data or fixed recipes.

What's Broken Today

Repetitive inbound palletizing strains labor

Inbound palletizing from floor-loaded trucks and containers is physically demanding, repetitive work. Associates lift, rotate, and stack thousands of cases per shift, often under time pressure to clear docks quickly — making retention difficult and turnover high.

Manual handling creates safety risk

Continuous lifting and pallet building increase the risk of strain and injury. Variations in box size and weight require frequent adjustments, leading to inconsistent pallet quality and higher physical load on workers.

Traditional automation can’t handle unknown cases

Conventional palletizers depend on prior knowledge of case dimensions and predefined stacking patterns. In inbound operations, where every truck contains different boxes and dimensions are only known at unload time, these systems break down or require extensive manual setup.

With the OmniPalletizer

Recent advances in real-time perception, decision-making, and robot motion enable a new approach to inbound palletizing.

Instead of requiring perfect item data or simplifying inbound flows to fit automation, the system adapts in real time — measuring each case as it arrives and generating pallet patterns dynamically as unloading progresses.

This makes it possible to automate inbound palletizing without changing upstream processes or relying on complete item master data.

How the OmniPalletizer Solves It

Jacobi’s OmniPalletizer is designed for inbound environments with unknown and variable cases.

It continuously:

Observes incoming cases in real time and measures case dimensions

Generates stable, dense single-SKU pallet patterns on the fly

Separates different SKUs onto dedicated pallets automatically

Executes fast, reliable robot motions while utilizing multi-pick to improve throughput

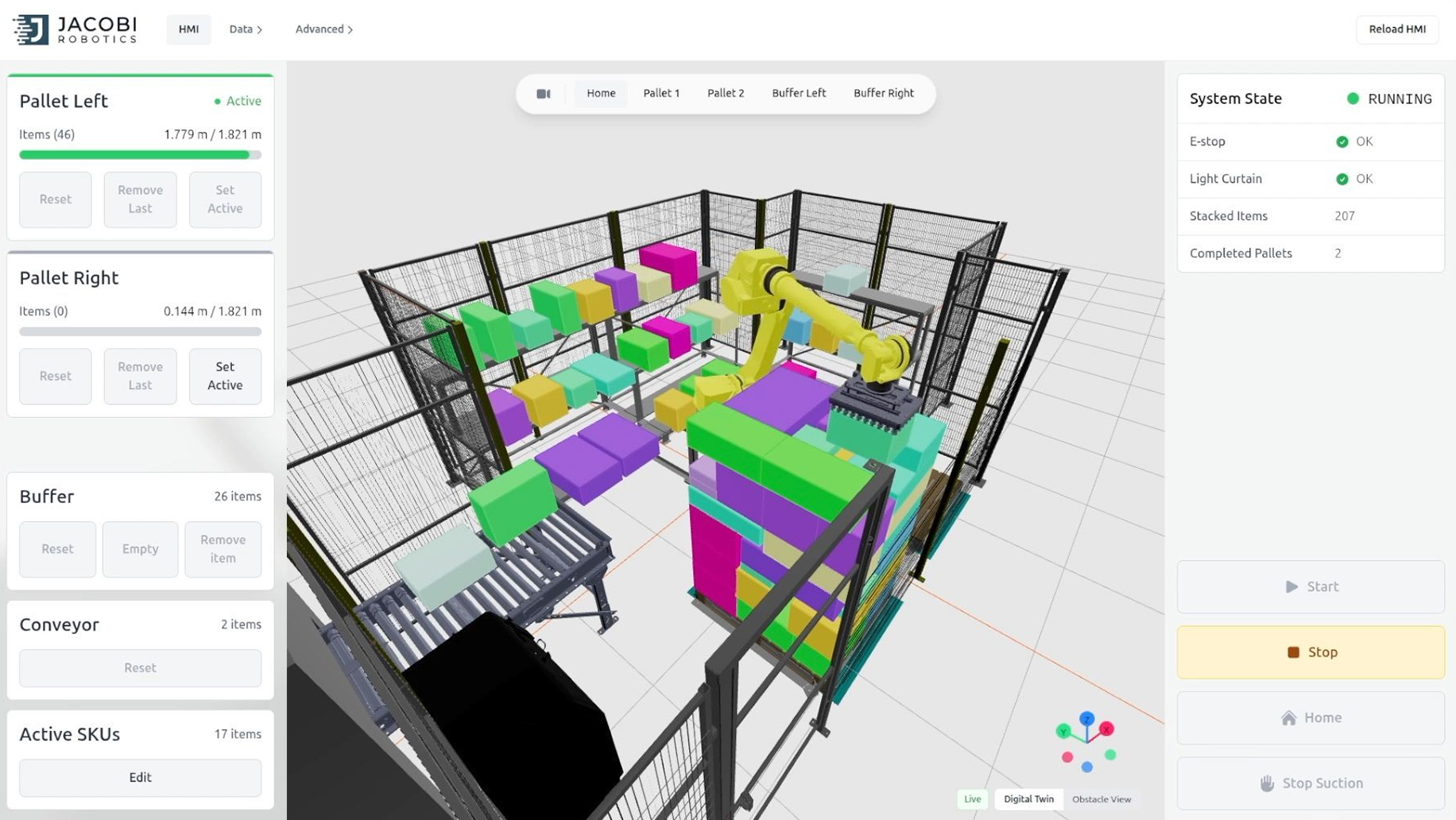

Alerts operators when it needs help with clear step-by-step instructions and a user-friendly interface

Business Impact

Reduced reliance on manual inbound palletizing labor

Improved safety and consistency at receiving docks

Faster truck and container unloading without pre-configuration

Automation that adapts to inbound variability, not the other way around