High-Volume Mixed-case Palletizing in Grocery Distribution

Automate Mixed-Case Palletizing in Grocery Distribution

Mixed-case palletizing built for grocery complexity.

Build stable, aisle-ready pallets across thousands of SKUs, automatically respecting crushability rules, chilled environments, and high-throughput demands — without rigid recipes or manual rework.

What's Broken Today

Repetitive palletizing drives turnover

Manual mixed-case palletizing in grocery DCs is repetitive, physically demanding work — often performed in chilled environments. Even when staffing exists, it’s difficult to retain associates in roles that combine constant lifting with cold conditions and high pace.

Manual handling increases injury risk

Building grocery pallets by hand requires frequent re-handling to protect crushable items like eggs and produce. Under time pressure, mistakes lead to worker strain, damaged goods, and inconsistent pallet quality.

Rigid automation breaks under variability

Conventional palletizers depend on fixed patterns and limited SKU assumptions. With thousands of SKUs, frequent assortment changes, and strict stacking rules, these systems break down and push work back to manual operations.

With the OmniPalletizer

Advances in real-time perception, decision-making, and robot motion enable a new approach to grocery palletizing.

Instead of simplifying the operation to fit automation, the system adapts to grocery reality — high SKU counts, fragile items, and constant change — without sacrificing throughput.

How the OmniPalletizer Solves It

Jacobi's OmniPalletizer is designed for mixed-case grocery environments.

It continuously:

Observes incoming cases in real time across thousands of SKUs

Reasons about stack stability, weight distribution, height, and crushability

Ensures fragile items are protected while maintaining dense, stable pallets

Executes fast, reliable robot motions suitable for high-throughput and chilled environments

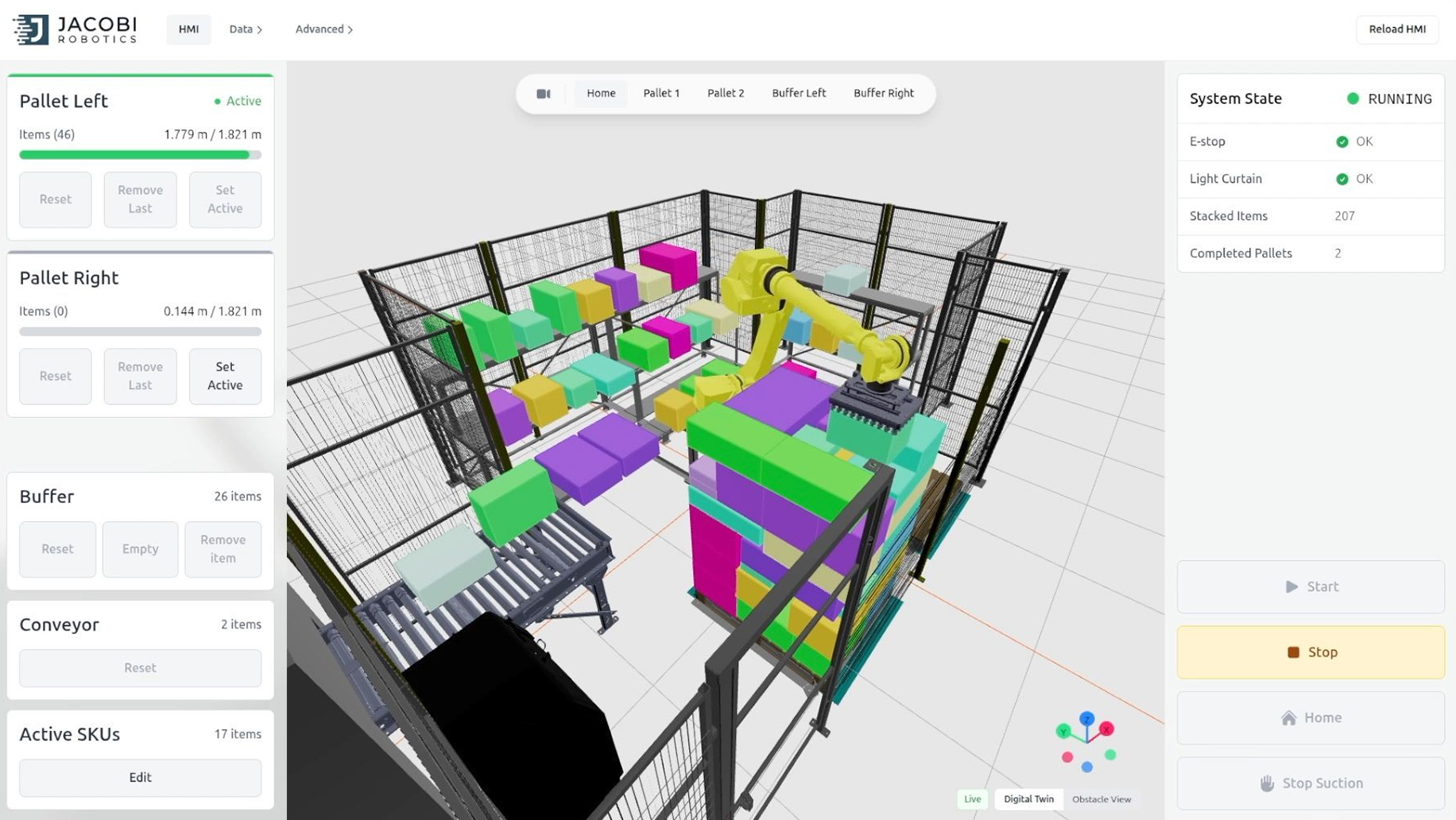

Alerts operators when it needs help with clear step-by-step instructions and a user friendly interface

Business Impact

Reduced damage to fragile and crushable goods

Denser, taller, more stable pallets, reducing freight costs

Reduced labor dependency and higher throughput without sacrificing pallet quality

Automation that scales with grocery SKU complexity