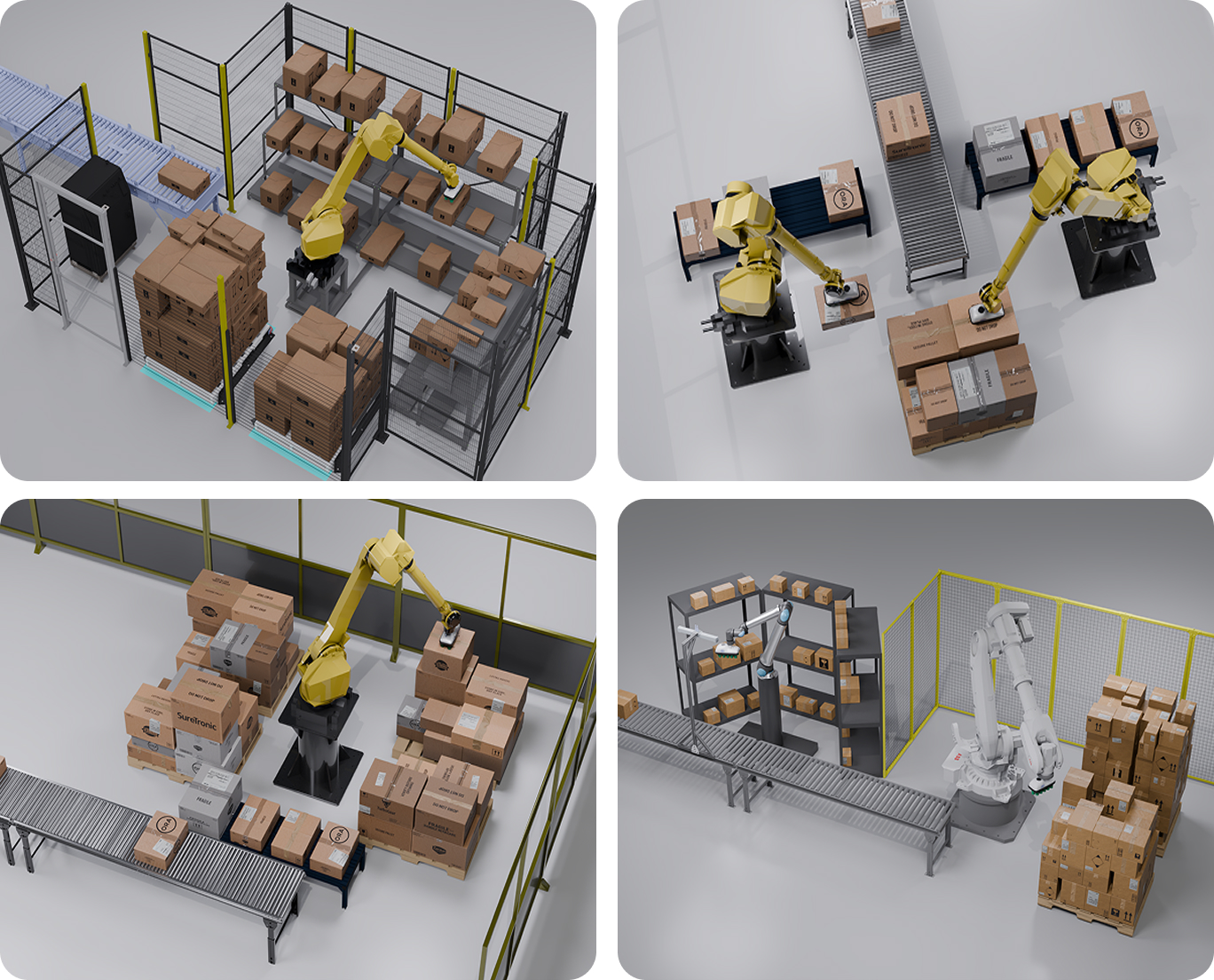

Mixed-Case Palletizing for Everyone

Works in brownfield reality

- Fits existing layouts - installs as a modular cell in current conveyor lanes and dock areas, without requiring new sequencing infrastructure.

- Coexists with manual work - run side-by-side during ramp-up, keep flexibility for exceptions, and maintain a clear fallback path when operations need it.

- Start small, scale confidently - begin with one flow or one cell, then add capacity and scope once results are proven.

Any case flow, any rules

- Handles the real "zoo" of flows - from lumpy pick-to-belt waves to live-loading docks and other unsequenced mixed-case streams.

- Honors your business rules by default - heavy-on-bottom, crush limits, aisle-/store-friendly grouping, stop sequencing, carrier/lane logic, and more.

- Adapts as reality changes - resilient to SKU drift, packaging variation, and shifting order profiles without brittle, template-driven recipes.

Proven in the digital twin

- Prove throughput before install - simulate with your actual SKU history and order mix, not synthetic assumptions.

- No surprises between demo and production - the same planning engine used in simulation is what runs on the floor.

- De-risk ROI and commissioning - align stakeholders early with evidence-based performance expectations and a clearer rollout plan.