Automating a High-Risk Bottleneck: On-the-Fly Mixed-Case Palletizing at a Defense Manufacturer

How a defense manufacturer partnered with Delta Technology and Jacobi Robotics to turn chaotic, injury-prone manual pallet building into a predictable automated operation—running in production on a FANUC industrial robot.

AT A GLANCE

- Workflow: fully random, real-time mixed-case palletizing (no sequencing, no pre-planning) that builds in real time

- Deployed by: Delta Technology

- Powered by: Jacobi Robotics' OmniPalletizer

- Robot: FANUC M-710iC/45M

- Status: live production operation, commissioned Q4 2025

The Workflow:

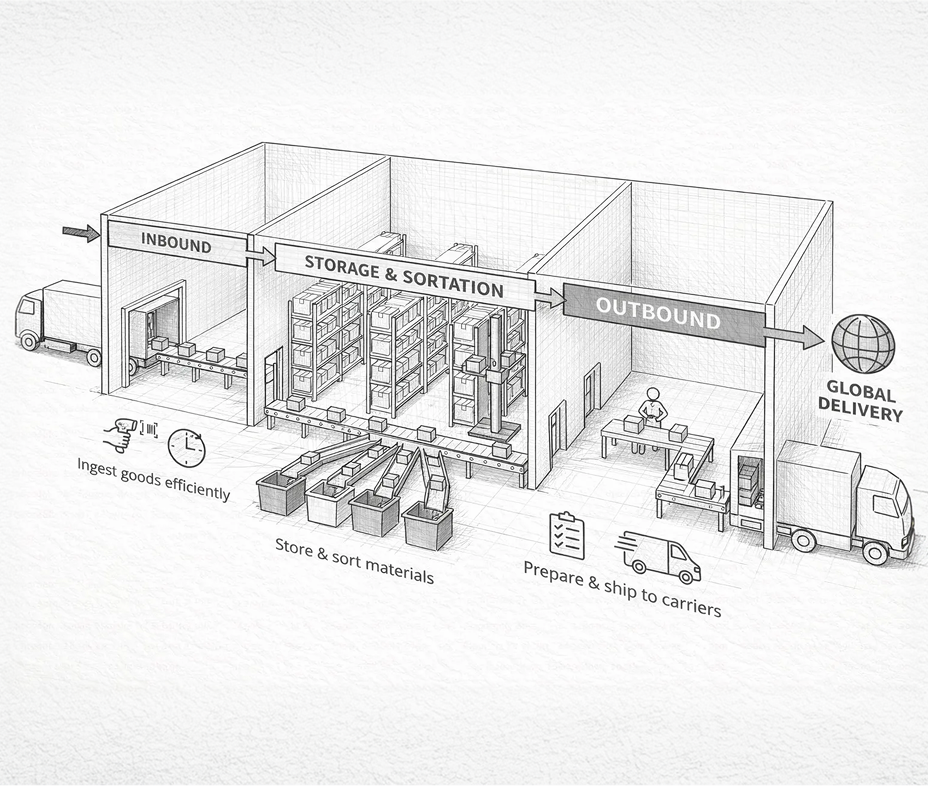

Fully Random, Real-Time Parcel Palletizing

- No opportunity to pre-plan pallet composition

- No fixing recipes defining what's next

What is mixed-case palletizing?

Mixed-case palletizing is building stable outbound pallets from random, unsequenced cases—without predefined recipes or advance knowledge of what comes next.

It’s the dock-edge problem most warehouses still do by hand.

The Problem:

Manual Palletizing and Rising Injury Risk

- Elevated injury risk from repetitive and awkward motion

- Increasing difficulty staffing palletizing roles

- A clear safety gap at the final step of an otherwise automated operation

The Solution:

Automating Mixed-Case Palletizing for Live Case Flow

1) Fits the existing operation — no sequencing required

2) Real-time planning for unsequenced case flow

Mixed-case palletizing is one of the most injury-prone jobs in the warehouse, especially in outbound environments where variability is the norm. Our goal is to remove people from repetitive, high-risk palletizing work without forcing customers or integrators to redesign their entire operation. This deployment shows that you can automate mixed-case palletizing safely, flexibly, and in a way that actually fits real production.

Max Cao

Co-founder and CEO at Jacobi Robotics

Why This Mattered to the Integrator

- Validate performance upfront using simulation rather than trial-and-error, with 0% error between simulated and actual cycle time

- Avoid brittle, rule-heavy palletizing logic

- Deliver a system that behaved predictably under real order fulfillment variability

- Treat mixed-case palletizing as a reusable subsystem, not a bespoke science project

- Reduce commissioning time and project risk, including a 2-week commissioning duration

From an integrator standpoint, mixed-case palletizing is traditionally where projects get complicated and risky. Using Jacobi allowed us to validate performance upfront, avoid brittle custom logic, and deliver a system that worked as expected from day one. It's a much more repeatable way to deploy mixed-case palletizing for parcel operations.

Larry Miller

Co-founder and COO at Delta Technology

Inside the OmniPalletizer

1. The Mixed-Case Palletizing Cell

2. The Operator Interface (HMI)

- Monitor pallet builds in real time

- Handle exceptions without engineering support

- Keep production running through shifts and demand spikes

3. Mixed-Case Palletizing in Action

The real breakthrough here is that the system doesn't rely on predefined pallet recipes or advance knowledge of the order. We're planning and validating every placement in real time, using physics-aware motion planning and continuous feedback, so the robot can make safe, stable decisions even when case flow is completely random. That's what allows this cell to work reliably in live parcel palletizing operations instead of controlled lab conditions.

Yahav Avigal

Co-Founder and CTO of Jacobi Robotics

The Outcome

- Operators removed from repetitive, high-risk palletizing tasks

- Improved safety at the dock edge

- Successful automation of fully random, real-time parcel palletizing, handling thousands of cases per day

- Faster deployment with lower integration risk, including a 2-week commissioning duration and 1:1 relationship between simulated and actual cycle time

- A scalable solution ready for future expansion, with dozens of SKUs in daily operation (and no limit on number of SKUs supported), boxes up to 60 lbs, and 2 destination pallets configurable by load carrier

- 100% stability on all pallets

- Up to 90% cube utilization—outperforming human stacking

- Operator training time less than one day

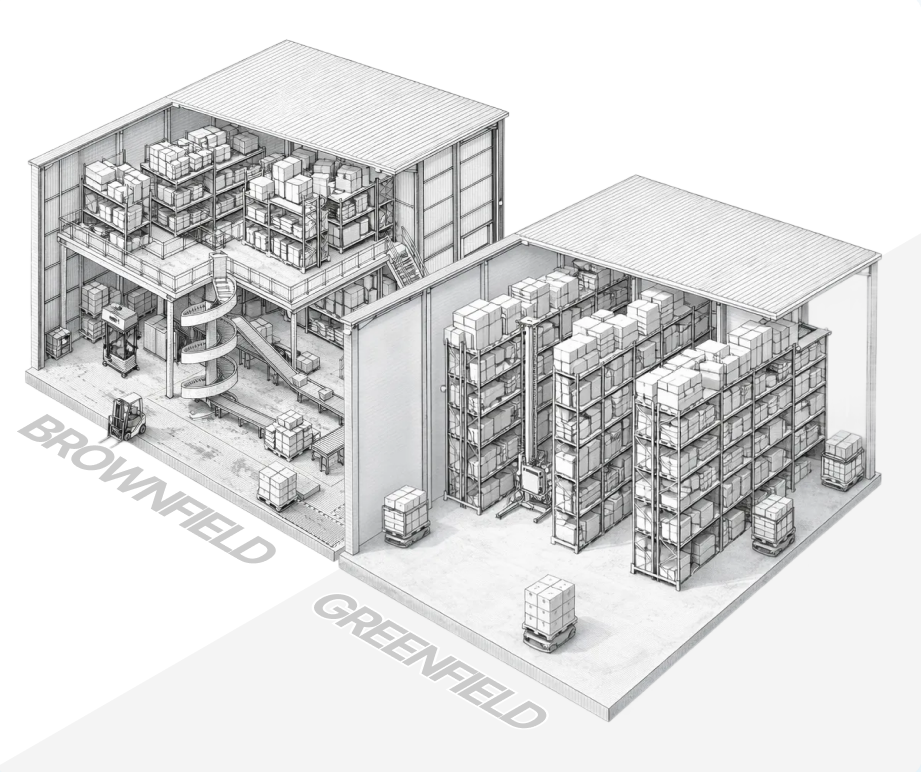

Mixed-case palletizing is no longer a niche demo capability. This deployment demonstrates a production-ready path to converting chaotic manual case handling into predictable automated operations—inside real brownfield constraints.