Data-Driven Palletizing Design

Design and Deliver Mixed-Case Palletizing Systems with Confidence

Data-driven palletizing design for system integrators.

Design, size, and sell mixed-case palletizing cells using real case-flow data and simulation — replacing guesswork and conservative over-engineering with evidence-backed throughput, ROI, and risk assumptions.

What's Broken Today

Pre-sales study relies on guesswork

In high-variability warehouses, there is no such thing as a “typical” mixed-case flow. SKU counts fluctuate, order waves change daily, and upstream systems behave differently at peak. Without a way to simulate real case flows, integrators are forced to design from analogues and intuition rather than evidence.

Uncertainty drives over-engineering

To avoid being under-spec’d, designs skew conservative: extra robots, oversized buffers, heavy sequencing infrastructure, or full AS/RS integrations. While this reduces technical risk, it inflates CapEx, weakens ROI, and makes solutions harder to sell — especially in brownfield environments.

Surprises surface after the deal is signed

True system behavior only becomes visible once detailed data arrives post-sale. At that point, changes to robot count, pallet positions, accumulation, or routing are costly. Redesign cycles erode margin, extend timelines, and reinforce the perception that palletizing automation is inherently risky.

With the OmniPalletizer

Recent advances in real-time perception, decision-making, and robot motion enable a new approach to inbound palletizing.

Instead of requiring perfect item data or simplifying inbound flows to fit automation, the system adapts in real time — measuring each case as it arrives and generating pallet patterns dynamically as unloading progresses.

This allows integrators to design, size, and commit to palletizing solutions with confidence — before hardware is ordered and before margins are locked.

How the OmniPalletizer Solves It

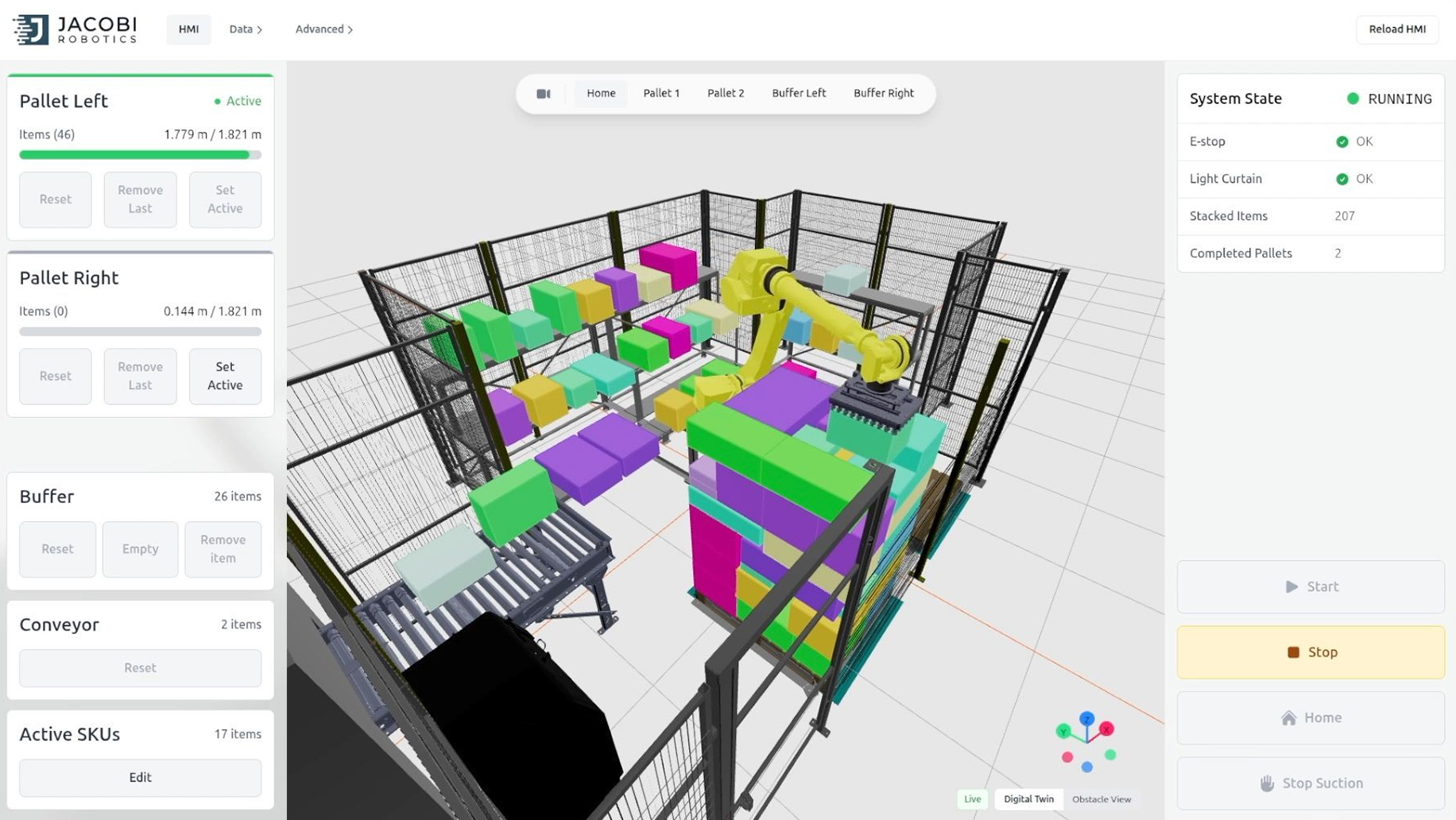

Jacobi's OmniPalletizer provides a digital-first approach to project planning, simulation, and delivery.

It enables users to:

Simulate mixed-case palletizing behavior using real or reconstructed case-flow data

Evaluate throughput, pallet quality, and buffer utilization under peak and off-peak conditions

Present customers with performance and ROI grounded in their own SKUs and business rules

Iterate on layouts quickly without committing to hardware or upstream sequencing changes

Right-size robot count, pallet positions, and accumulation based on evidence — not assumptions

Because simulation and production use the same planner, what is demonstrated pre-sale is representative of what will run on the floor.

Business Impact

Faster pre-sale concepting and fewer internal design iterations

Leaner palletizing systems with lower CapEx and stronger ROI

Narrower, defensible throughput and performance commitments

Reduced redesign risk during delivery and commissioning

Differentiated proposals that work in brownfield, imperfectly sequenced environments

The New Standard for Palletizing

OmniPalletizer becomes a standard palletizing brain — one that can be reused across projects, layouts, and robot platforms.

Instead of rebuilding a custom palletizing logic stack for every mixed-case opportunity, integrators can focus on system design, value engineering, and delivery — backed by a planner that scales with real-world variability.