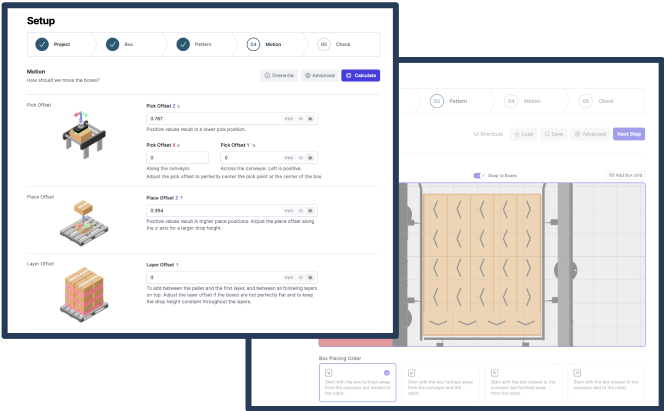

Setup

Load CAD and define robot environment

Off-the-shelf and zero-teach solutions that you can quickly configure and deploy with your choice of hardware.

For pick-and-place operations, Jacobi's software eliminates the need for complex programming, enabling deployment of cells in just days and allowing operators to easily reconfigure additional SKUs.

When robots need to follow precise paths, such as for dispensing, welding, or gluing, Jacobi’s software automatically extracts the paths and programs optimized robot motions.

A simple workflow that allows the end user to update and configure projects seamlessly

Load CAD and define robot environment

Set parameters using intuitive UI

Activate the application with a single click

Jacobi applications run on a simple industrial PC and communicate in real time with the robot, peripherals and HMI

Control and receive I/O signals from peripherals such as light curtains, area scanners, conveyors and EOAT.

Real-time motion streaming to ensure optimal motions while enforcing vendor-provided safety configurations.

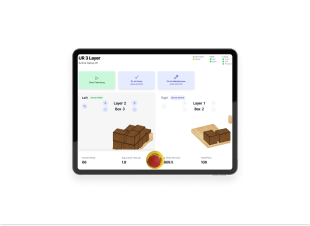

Use our intuitive HMI to operate the application or develop your own using our HMI-API.

We partner with you to develop solutions that require advanced capabilities, such as vision feedback and optimized external axis motion

"Jacobi's AI technology gives us a significant competitive edge by streamlining deployment and reducing manual programming. This partnership enables us to take on more complex projects while maintaining rapid delivery times, giving us more room to innovate and grow our business."

Read more about Jacobi and Torfresma USA

"Working with Jacobi, I've found their innovative palletizing software to be a game-changer. It stood out against the many other tools I evaluated throughout my career. It streamlines programming across different robots and hardware, enhancing deployment and remote operations, all make my work faster and more efficient. Jacobi is truly redefining industrial automation from my perspective."

Read more about Jacobi and Formic

Unlimited Electro

Unlimited Electro"Jacobi Robotics has transformed our palletizing processes. Their innovative software integrates seamlessly with different robotic systems, making deployment quick and remote operations efficient. The intuitive interface has significantly reduced programming time and increased our productivity. Jacobi is a true partner in automation, and their palletizing solutions are top-notch. We couldn't be more satisfied."

Read more about Jacobi and Unlimited Electro